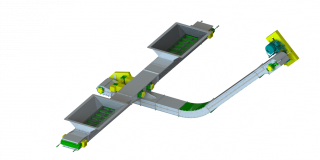

The Sukup Double Run Conveyor is an efficient grain handling system designed to reduce grain damage while maximizing throughput and is more economical and effective than portable augers. Sukup's Double Run Conveyor is engineered for gentle and efficient grain movement, replacing the need for a roof auger, transfer auger, dryer take-away auger, and even a permanently installed transport auger. With its compact design, the Double Run Conveyor operates smoothly and quietly, requiring minimal maintenance. The Double Run Conveyor features 100% UHMW paddles pre-attached to the chain.

The Double Run Conveyor is also highly adaptable, offering optional intermediate discharge gates for horizontal applications, further enhancing its versatility for various grain handling needs. Its flexible design allows for inclining sections, enabling efficient grain transfer while maintaining high capacity and grain quality. Additionally, Sukup provides the option to add 32° and 45°bend sections to a Double Run Conveyor allowing you to feed your dryer directly from your hopper bin with one simple, high-capacity conveyor. Drive-over hoppers are available in 5', 8.5' & 10' for receiving systems used in conjunction with bend sections.

Standard Features

- Extremely gentle on grain with less horsepower used

- 1,500 BPH - 10,000 BPH capacities

- On average 4-5 times longer life span than an auger

- Compact design and smooth, quiet operation

- Heavier gauge tubing standard

- Head or tail drive

- Double-Run Conveyor runs can be longer than an auger

- Double-Run Conveyors can be set at up to a 60˚incline

- Set-up time for a Sukup Double-Run Conveyor is about half that of other companies because the paddles come pre-attached to the chain

- UHMW paddles eliminate steel-to-steel contact

- Corrosion-resistant Acme thread take-up screws at head

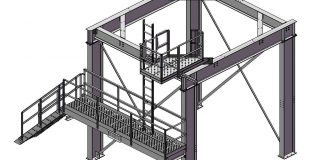

Product Accessories

- Drive at head

- Head discharge available at 45˚, 60˚ and 90˚ angles

- Intermediate Discharge and ground control kits

- Dump-through tail section with gate

- Cover and extension for hopper

- Truss systems available

- 32˚ and 45˚ bends

- Intermediate discharge gates and ground control kits available

Product Features

- Standard Double Bearing Support on Drive

- Advanced Inlet Design to Minimize Grain Damage

- Configurable Tail Drive

Lawler, IA